1983 SAE Super Mileage Competition

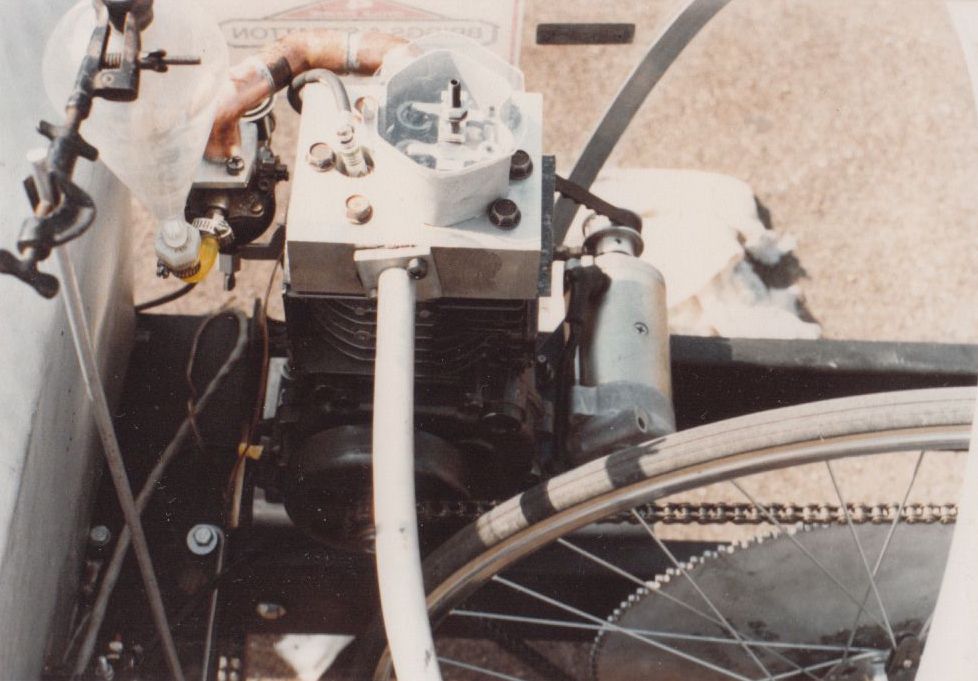

I went to school for mechanical engineering, in Tucson at the University of Arizona, graduating in 1983. My senior design project was to work with several other students, and build a car to compete in the SAE Super Mileage Competition. I worked on the engine, concentrating on making an improved cylinder head, while the other students made the chassis, body, a differently modified engine, etc. We were given a 2 Hp Briggs & Stratton engine, and we could do pretty much whatever we wanted to it. I decided that the best approach would be to make a high compression overhead valve head for it, and operate the car at full throttle, accelerate then shut off and coast. The car only had to average 15 mph in the competition, and this type of driving was allowed. I made a couple cylinder heads from a 2" thick chunk of aluminum. I still have the first one, but we used the second one for the competition, as it worked noticably better. I documented the reduction in BSFC, using a little water brake dyno and a balance. I also won the design project class competition (a fancy HP calculator was the prize), because I was the only student who actually tested his design!

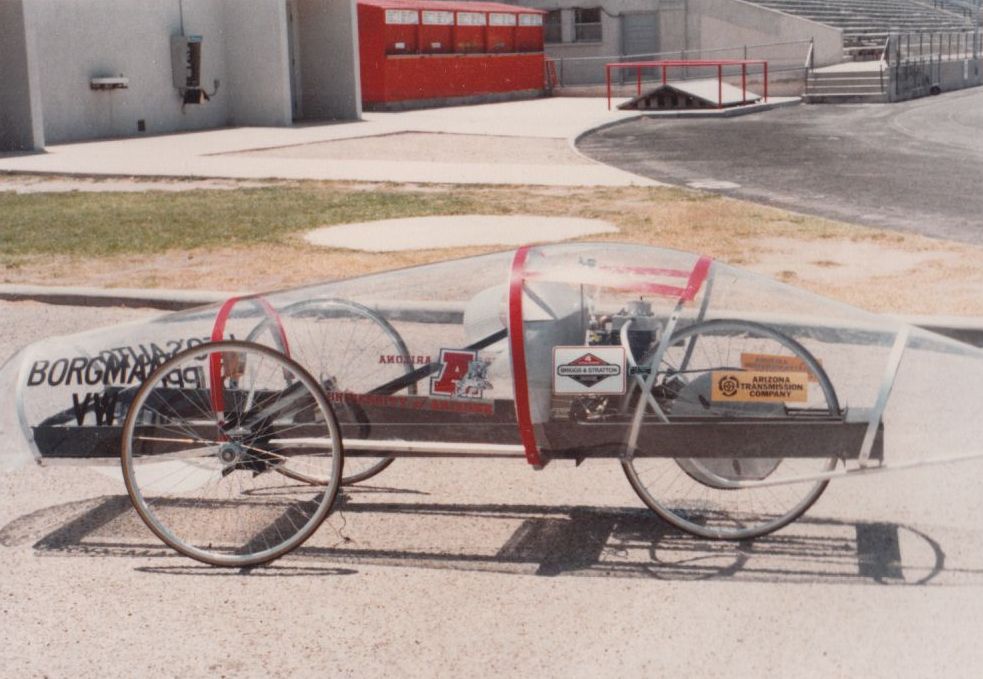

The frame was made of structural fiberglass channel, bonded together. The body was thin polycarbonate. The nose was made into a bubble by making a form with a hole in it, heating in an oven until the plastic was soft, then inflating with air. The seat was just some plastic webbing, which was not very strong, but it was light. The steering was by foot, push the right pedal to steer right, and the left pedal to steer left. I think there was a rear bicycle brake, operated by hand, but it was not very effective. The engine was started with an electric motor, driving the B&S ball type clutch that was originally used with the pull cord starter. We made a sprocket for a toothed belt, and powered the motor with a motorcycle battery. I think the rear drive sprocket was made by a previous year team, from aluminum plate, using a mill and rotary indexing table.

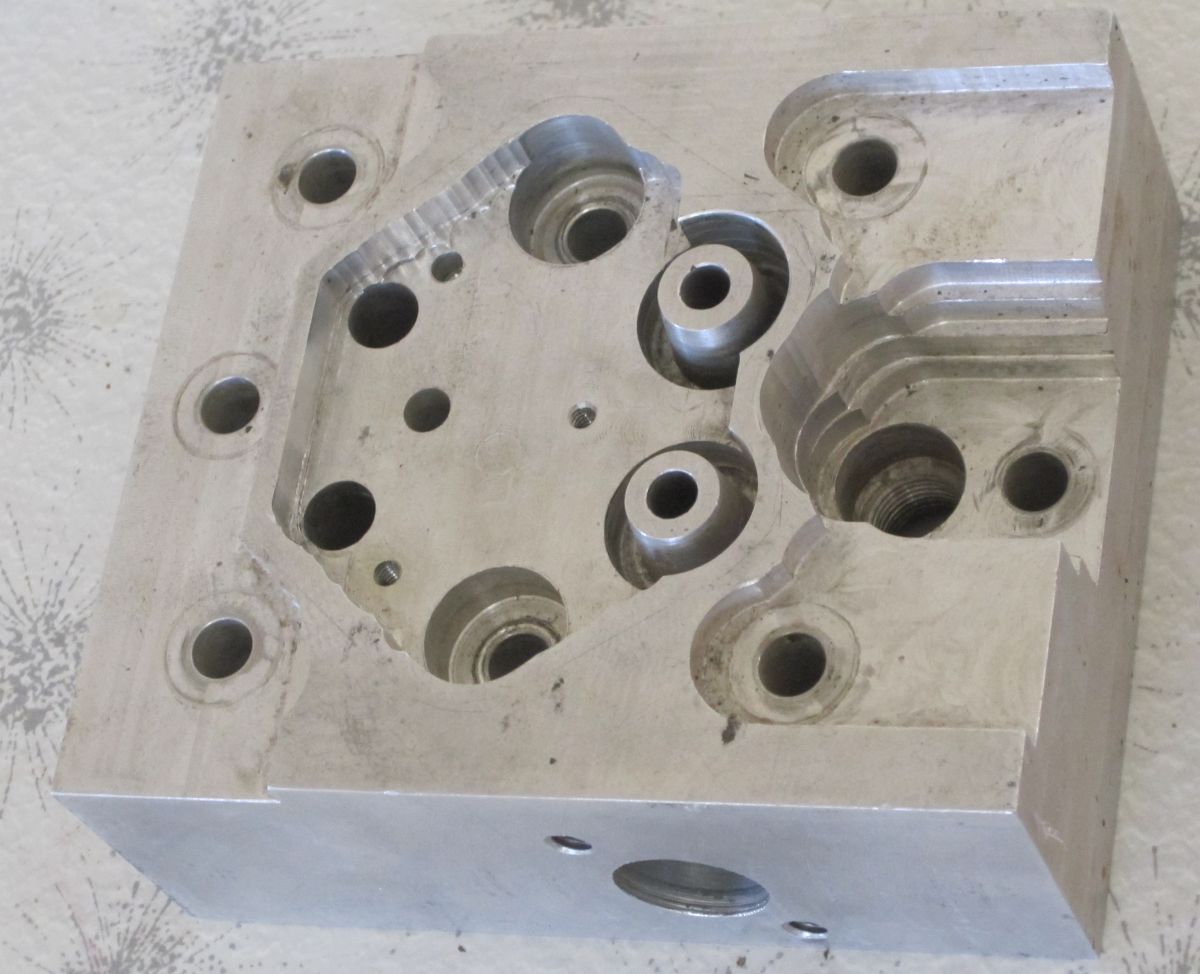

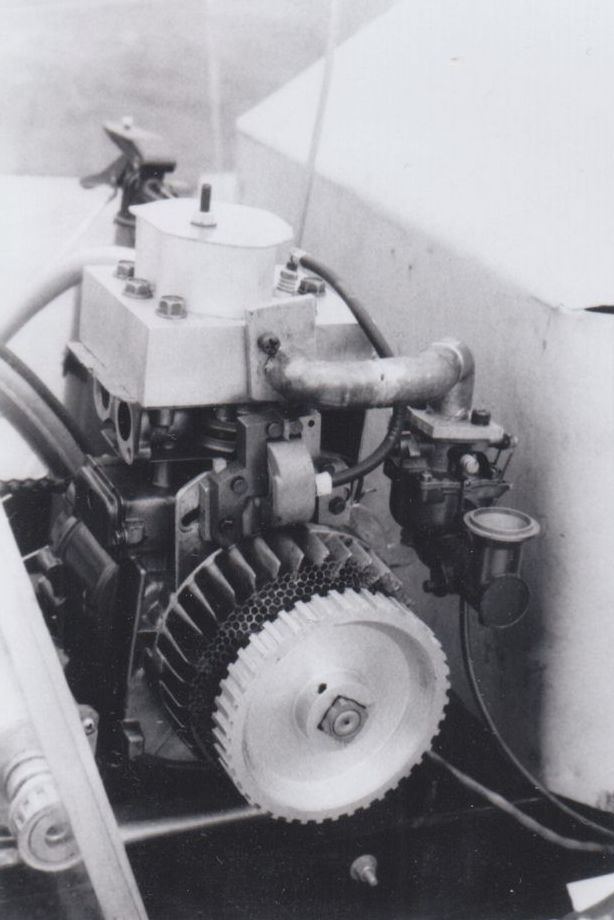

The engine used the stock bore and stroke. I made this head using the mill, it had angled valves, with a wedge shaped combustion chamber. The valves were shortened originals, using the bare aluminum as the seats. There was no cooling system, just the thermal mass of the big chunk of aluminum. There was no lubrication system, just some grease added to the valve guides and rocker arms during assembly. I made an adjustable timing mount for the coil, and the engine had the new electronic ignition system that B&S had just introduced, so there were no points to worry about. The intake manifold was just a crude plumbing assembly, the exhaust was slightly better aluminum tubing, bent to a gentle curve.

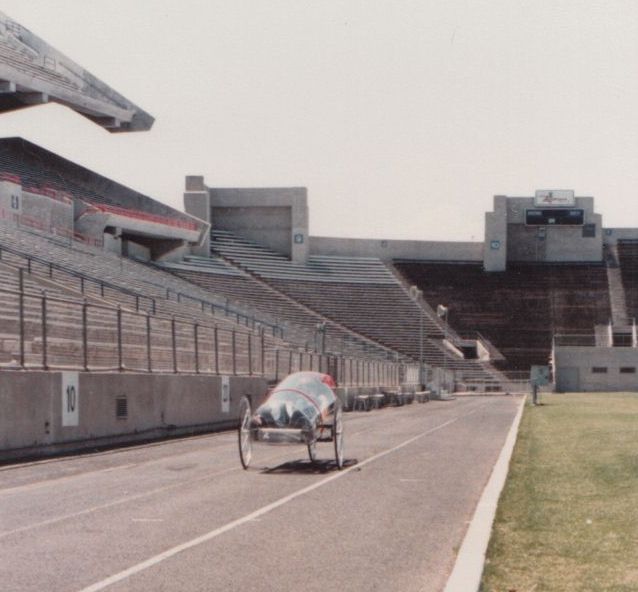

School was over in the middle of May, and the SAE competition was in the beginning of June, in Michigan. We got the car put together just about the time school ended, and made some test runs on the track at the stadium, just before it was time to leave for the competition. Some quick calculating (using a soda can's metric and US volume measurements for conversion) showed we were getting about 472 mpg.

I got to drive, and the car was not really set up for high speed steering, stopping, etc. I managed to crash into a trash can, and did some serious damage to the car. The nose was crunched, the frame broken, the wheels bent, the steering broken. The other students pretty much gave up at that point. We all had raised some money for the trip from local sponsors, and I ended up getting the money and being the one to go on the trip.

I had two choices for transportation: my big block powered 59 chevy pickup (equipped with 4.56 gears), and the old family station wagon, a 1967 Plymouth Fury III with over 200k miles. I picked the wagon, and somehow managed to talk my fiancee Janet into going with me. We had several hundred dollars, which we figured would be enough money for gas, a few motel stays, and some food. I was staying at my brother's house on Grant Road at the time. I took the mileage car apart, and we loaded up the wagon with the parts.

The Plymouth had been our family car since 1969. We had taken it on several vacations to Minnesota, Mexico, and Texas. On three of those trips, it had lost a rear wheel bearing. We also lived in Mexico in Baja California in the early 70s, and had driven the car back and forth several times between there and Tucson. On the last trip, moving the last of our possessions home, the engine blew, I think near Gila Bend. Dad bought a rebuilt engine from Montgomery Wards, and had it installed. A few years later, I learned how to fix cars by keeping it running when I got old enough (age 14), so I was pretty familiar with it--I had done a valve job, lots of ignition/carb work, overhauled the transmission, replaced the rearend, etc.

Our trip got off to a great start, somewhere in New Mexico, the Plymouth started to run badly. I played around with various things, we drove carefully and kept fiddling with the engine, We finally ended up going to a tune up shop, as I didn't have any test equipment with me--the points were out of adjustment, and getting the dwell set properly was mostly all it needed. While we were there, one of the mechanics noticed there was a bird nest under the hood of the car, near the radiator.

When we got to Battle Creek, Michigan, home of the Eaton proving ground, we had to put the mileage car together.

The engine was way too powerful to run the car efficiently at the required 15 mph speed, and my research with the engine had shown that best BSFC was at near full throttle operation. So, our plan for running the car was to accelerate at full throttle up to about 30 mph, then shut off the engine and coast down to about 5 mph. Janet had a sign and a stopwatch, and could time how far I'd gone in how long, so we could tell if I needed to speed up to maintain the required 15 mph average, and write something on the sign to let me know. We got the car together and running, and I took it for a first run. I managed to run off the course, and broke the "seat". After some more repairs, I made a final run, and made four of the required six laps, and the starter quit working--the B&S ball starter clutch was not up to the torque of the electric starter motor, and came apart. We got the DNF...but they did calculate our approximate fuel mileage at a bit over 500 mpg.

While on the trip, Janet learned that she had been accepted for a summer job at Ft Huachuca, and needed to get home by Sunday, and it would take at least a couple days to drive. I dropped her off at the Chicago airport, and she flew home. I took my time getting home, stopping to visit several relatives in the midwest--my uncles in Minneapolis, my grandfather in Glenwood, a great aunt in South Dakota, another great aunt and uncle in Colorado. Somewhere in New Mexico I had to buy a tire for the Plymouth, as the old bias tires were not very good. But I did have enough gas money to make it home.

My brother cut this article out of the local newspaper.

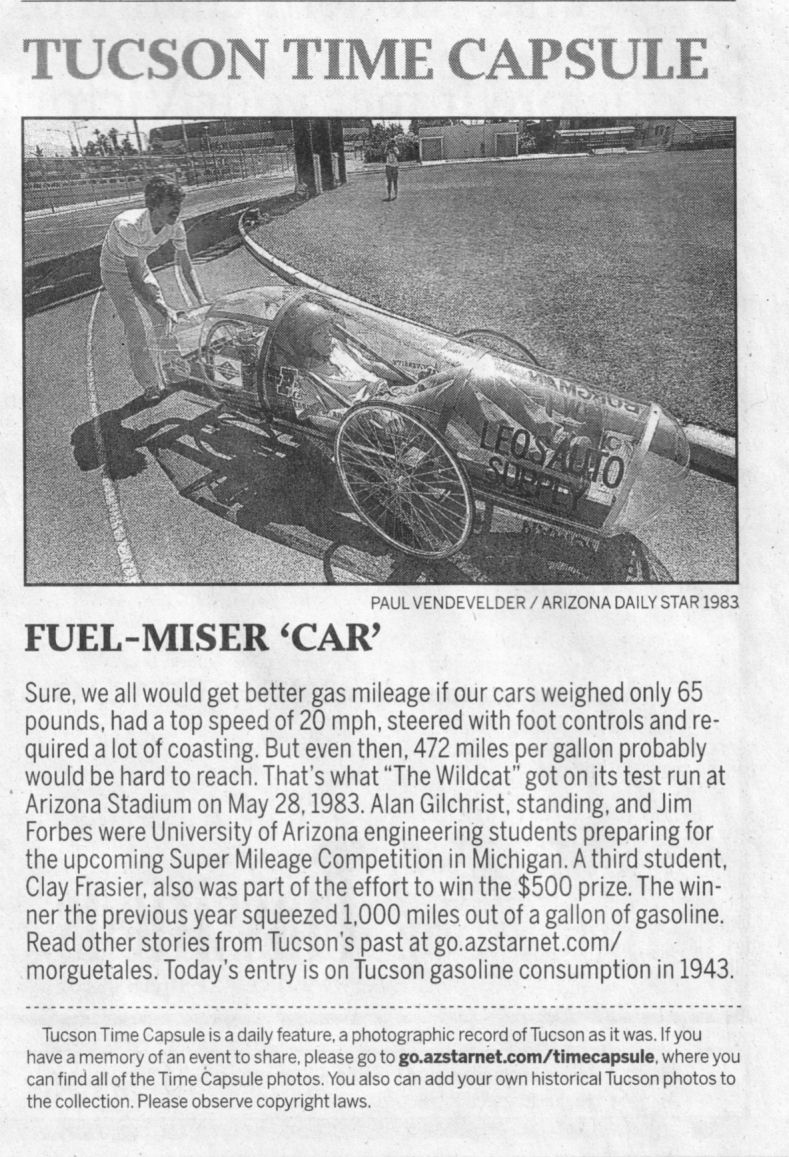

After 25 years the Tucson paper dug up the story for a repeat!

And here are a couple pictures of the head I made, and didn't use on the car.